- READY STOCK OF STAINLESS STEEL PIPES, CARBON STEEL PIPES & LOW ALLOY STEEL TUBING IN MALAYSIA & DUBAI

-

-

-

Girgaon, Mumbai - 400004

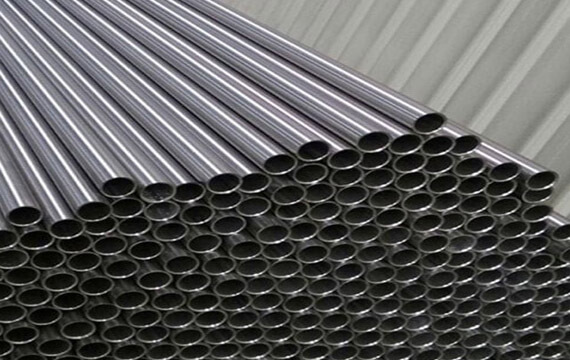

Stainless Steel 310H Welded Tubes

Stainless Steel 310H Welded Tubes, crafted by Kamal Piping, stand out as an exceptional choice for high-temperature applications. As Manufacturers, Suppliers, Stockists, and Exporters of Stainless Steel 310H Welded Tubes, we take pride in delivering top-quality products with unique features and superior performance.

Stainless Steel 310H Welded Tubes, Stainless Steel 310H Welded Tubes Manufacturers, Stainless Steel 310H Welded Tubes Suppliers, Stainless Steel 310H Welded Tubes Stockists, Stainless Steel 310H Welded Tubes Exporters

These austenitic stainless steel tubes are characterized by their elevated nickel and chromium content, ensuring remarkable resilience in harsh environmental conditions. The distinct advantage of Stainless Steel 310H lies in its outstanding resistance to oxidation and corrosion, making it a preferred material in diverse industries. Our SS 310H Welded Tubes are available in various shapes, forms, and lengths, providing flexibility for different applications. These tubes excel in environments requiring high temperatures, showcasing exceptional oxidation resistance, ductility, and weldability. Their solid and durable construction makes them a reliable choice for a wide range of industrial and commercial facilities globally.

Stainless Steel 310H Welded Tubes Manufacturers in India, Stainless Steel 310H Welded Tubes Suppliers in India, Stainless Steel 310H Welded Tubes Stockists in India, Stainless Steel 310H Welded Tubes Exporters in India

It's crucial to note that the main distinction between SS 310 and 310H lies in their carbon content. SS 310 tubes, with lower carbon content, are suitable for lower temperature applications. On the other hand, Stainless Steel 310H tubes, with a higher carbon content, offer increased strength and resistance to high temperatures, making them ideal for demanding environments like furnaces, heat treatment, and chemical processing equipment.

Kamal Piping prioritize delivering products with unique characteristics, ensuring that each Stainless Steel 310H Welded Tube meets high standards. The utilization of advanced manufacturing processes guarantees a distinctive blend of corrosion resistance, strength, and weldability.

Stainless Steel 310H Welded Tubes Manufacturers in Mumbai, Stainless Steel 310H Welded Tubes Suppliers in Mumbai, Stainless Steel 310H Welded Tubes Stockists in Mumbai, Stainless Steel 310H Welded Tubes Exporters in Mumbai

In addition to their resistance to carburization and thermal cycling, our SS 310H Welded Tubes are designed to withstand high pressure and corrosive environments. This robust performance makes them a reliable choice for critical applications where durability is paramount.

In conclusion, our commitment as Manufacturers, Suppliers, Stockists, and Exporters ensures that Stainless Steel 310H Welded Tubes by Kamal Piping not only meet but exceed industry standards. Choose our tubes for unparalleled quality, unique features, and the assurance of a product crafted to withstand the most demanding conditions.

Stainless Steel Welded Pipe Specifications

| Pipe Specifications | ASTM A312 304, ASTM A358 304, ASTM A790 304, ASTM A409 304, ASTM A376 304, ASTM A813 304, ASTM A814 304 |

|---|---|

| Tube Specifications | ASTM A312 304, ASTM A358 304, ASTM A790 304, ASTM A409 304, ASTM A376 304, ASTM A813 304, ASTM A814 304 |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| SS 304 Pipe Thickness Range | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| W.T | SCH5S, SCH10S, SCH40S, SCH80S, SCH160S, etc. (0.5-12mm) Or non-regular size to be tailored as required |

| Type | SS 304 Seamless Pipes | SS 304 ERW Pipes | SS 304 Welded Pipes | SS 304 Fabricated Pipes | SS 304 CDW Tubes, LSAW Pipes / Seam-welded / Redrawn |

| Form | SS 304 Round Pipes/ Tubes, SS 304 Square Pipes/ Tubes, SS 304 Rectangular Pipe/ Tubes, SS 304 Coiled Tubes, SS 304 “U” Shape, SS 304 Pan Cake Coils, SS 304 Hydraulic Tubes |

| Length | Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded |

| End Protection | Plastic Caps | Outside Finish: 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

| Finish | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| External Coating | 3LPE / 3LPP/ FBE/ DFBE/ PP |

Equivalent Grades of SS 310H Pipes & Tubes

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS 310H | – | S31009 | – | – | – | – | – |

Chemical Composition of SS 310H Pipes-Tubes

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 310H | min. | 0.04 | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.10 | 2.00 | 1.00 | 0.045 | 0.030 | 26.0 | 21.0 | |||

SS 310H Pipes/Tubes Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 310H | 515 | 205 | 40 | 95 | 217 |